Introduction

Small Bore Tubing (SBT) assemblies are widely used in oil and gas processing plants, refineries, power generation stations, and petrochemical facilities. They connect instruments to the process for monitoring, control, and protection. The integrity of these assemblies is critical to prevent failures that could lead to leaks and serious incidents.

Complexity and Vulnerabilities

Due to their complexity and extensive use, SBT installations are vulnerable to failures caused by improper installation and/or lack of effective inspection and maintenance programs. This means that if best practices are not applied throughout the entire lifecycle of the SBT assembly, there is a relatively high probability of an integrity failure occurring during service. Recognizing SBT assemblies as potentially high-risk is essential. Large organizations have directed investments toward employee training and inspection services. However, if this practice is only reactive, there is a high potential for recurring failures. Therefore, SBT management must be embedded in the company’s culture.

Statistical Data

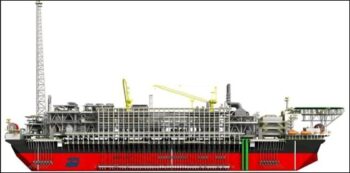

It is estimated that a production asset or FPSO contains, on average, over 15,000 components. Initial inspections typically reveal a failure rate exceeding 40%, with over 80% of these due to insufficiently tightened connections. On average, one hydrocarbon leak is detected per inspection round.

An improperly tightened and leaking connection can lead to production shutdowns and allow fugitive emissions into the atmosphere. Therefore, adopting practices that ensure system integrity is of utmost importance.

Design

SBT assembly design must follow the company’s engineering policies and specifications, considering factors such as safety, service conditions, static and dynamic loads, and material selection. It is essential to provide detailed information for safe and efficient installation, including drawings, instructions, and material lists.

Design Activities:

- Initial Assessment: Consider system performance standards and apply threat mitigation measures.

- Material Selection: Ensure compatibility of materials with internal fluids and external environmental conditions.

- Tubing and Fittings Specification: Define dimensions, wall thickness, and appropriate types of fittings.

- Valve Selection: Choose suitable valves for isolation and control, considering safety requirements.

Installation

Installation must be carried out by qualified personnel, following the work standard defined during the design phase. Material handling, inventory control, and component segregation must be considered to avoid mixing different materials. Proper tools must be available on-site.

Installation Practices:

- Handling and Inventory Control: Implement strict material segregation policies and ensure clear component identification.

- Initial Review: Review the design documentation and conduct a site survey before installation to ensure proper execution.

- Connections: Ensure fittings are correctly identified and installed according to specifications.

Inspection and Maintenance

SBT assemblies require regular inspection to ensure ongoing integrity. Inspection programs must be planned and implemented to identify and correct issues such as loose fittings, corrosion, and vibration. Maintenance should include isolation procedures and pressure testing after interventions.

Inspection Procedures:

- Visual Inspection: Check fittings, supports, mechanical damage, and corrosion.

- Intervention Management: Conduct risk assessments and prioritize corrective actions based on failure criticality.

Support and Protection

Proper support of SBT assemblies is crucial to prevent failures due to static and dynamic loads. Assemblies must be designed to accommodate thermal expansion and vibration, using optimized configurations and appropriate support spacing.

Support Considerations:

- Tubing Assemblies: Protect fittings from relative movement and ensure adequate support.

- Structural Assemblies: Consider thermal expansion and relative movement between tubing and structure.

Competence and Training

The competence of personnel involved in the design, installation, and maintenance of SBT assemblies is fundamental. Training and assessment programs must be implemented to ensure all involved are properly qualified.

Competency Requirements:

- Managers and Supervisors: Training and experience to manage SBT activities.

- Designers: Competence in SBT design and practical experience.

- Installers and Technicians: Training and competency assessment for SBT installation and maintenance.

Conclusion

Following these guidelines helps ensure the safety and integrity of SBT assemblies throughout their lifecycle, minimizing risks and improving operational efficiency. The implementation of rigorous design, installation, inspection, and support practices, along with training and competency programs, is essential for successful small bore tubing operations.

Polar, with its new process and instrumentation business unit, is prepared to assist clients in handling SBT. With technical expertise and customized solutions, Polar can provide comprehensive support from design to maintenance, ensuring the integrity and efficiency of small bore tubing assemblies